Vacuum Conveying System Design Calculation

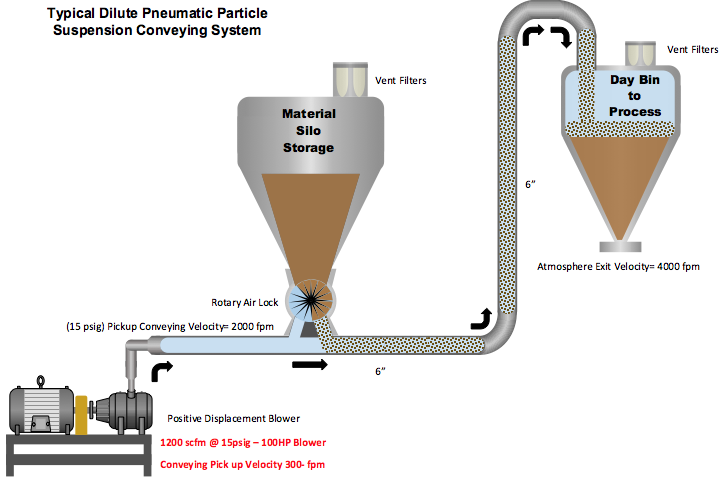

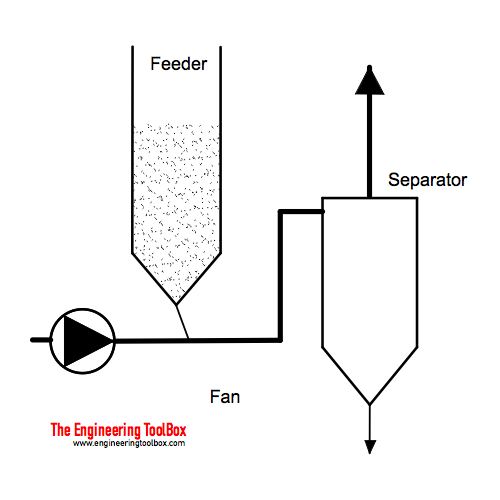

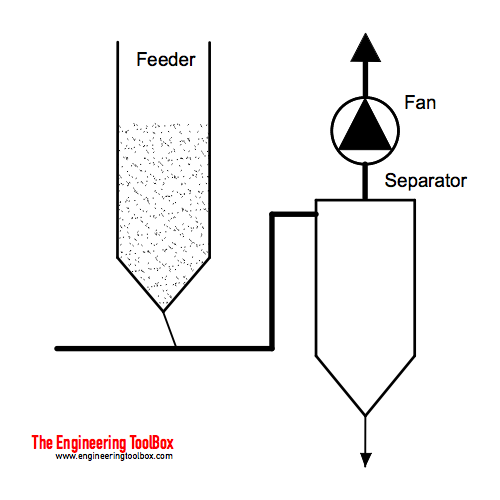

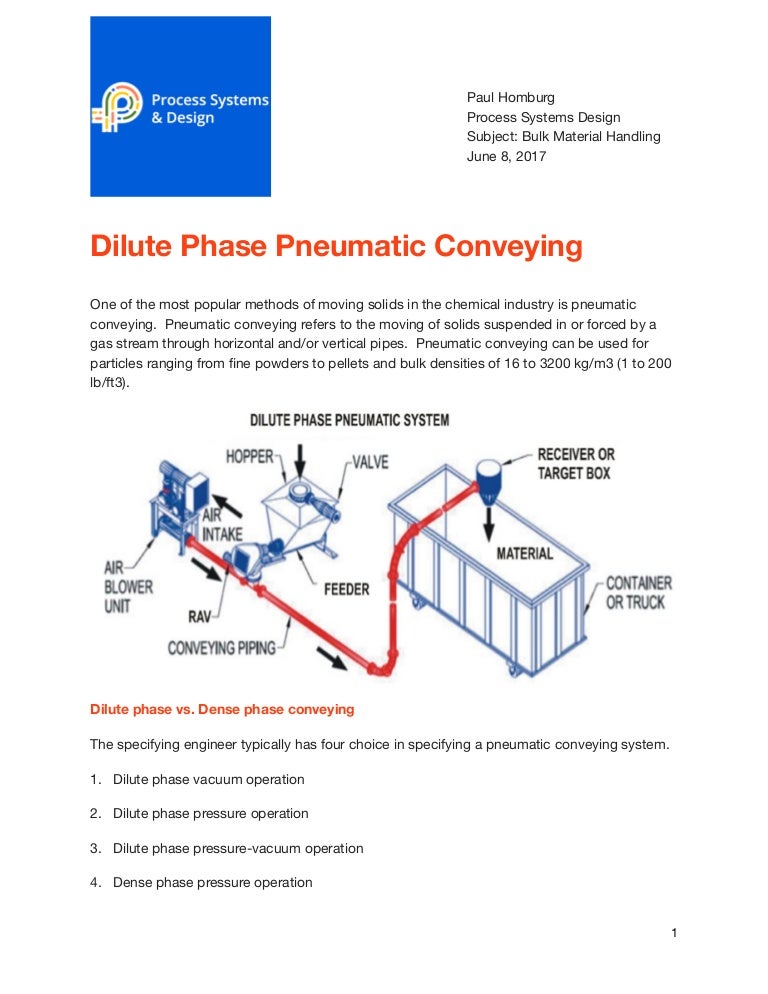

Vacuum conveying system design calculation. In a dilute phase system. The material is fed into the conveying line on a continuous basis by vacuum which is supplied by a low pressure positive displacement blower. The size is 20 5mm 80.

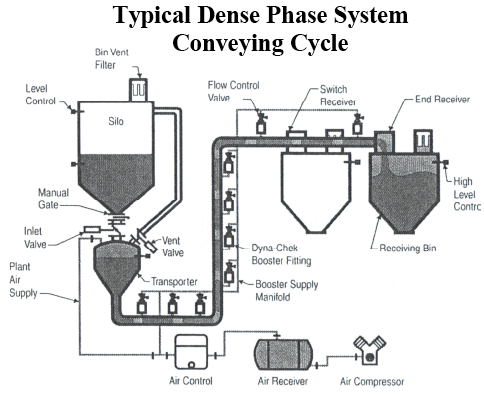

Conveying system is that material is transferred in close loop thereby preventing the environmental effect on the material and vice versa. In vacuum- and pressure pneumatic conveying calculations the used product properties are identical. Motivation The goal is to develop a numerical model of the vacuum system whether simple or complex.

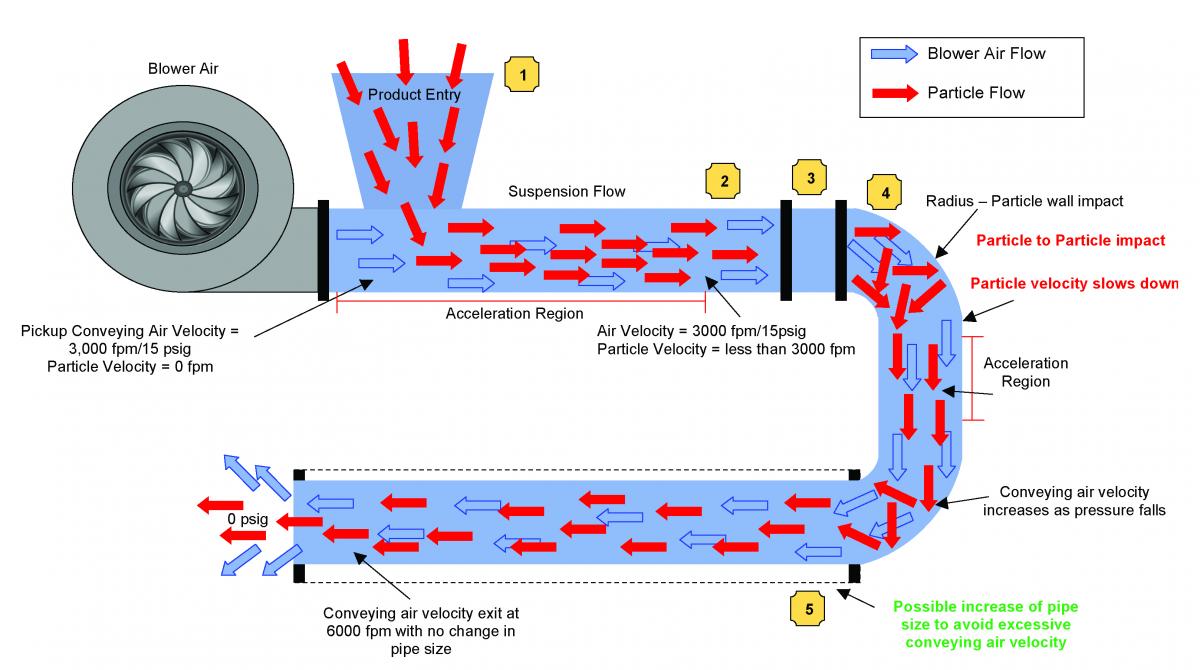

Conveying system designer an excellent opportunity for optimal system design. Q A x V ie. 1Friction of the gas against the pipe wall.

Vacuum Conveying is the process of moving bulk dry materials such as powders from place to place within a factory using suction. Since air is being pulled into the conveying line and not pushed out should a leak occur in the line the vacuum design wont allow the toxic material to escape as easily as a pressure system would. Calculate the volume of free air Qs required.

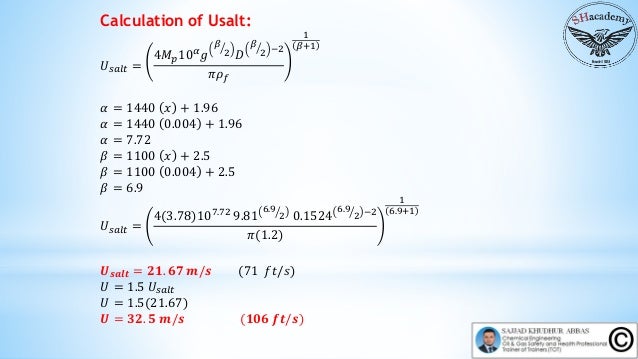

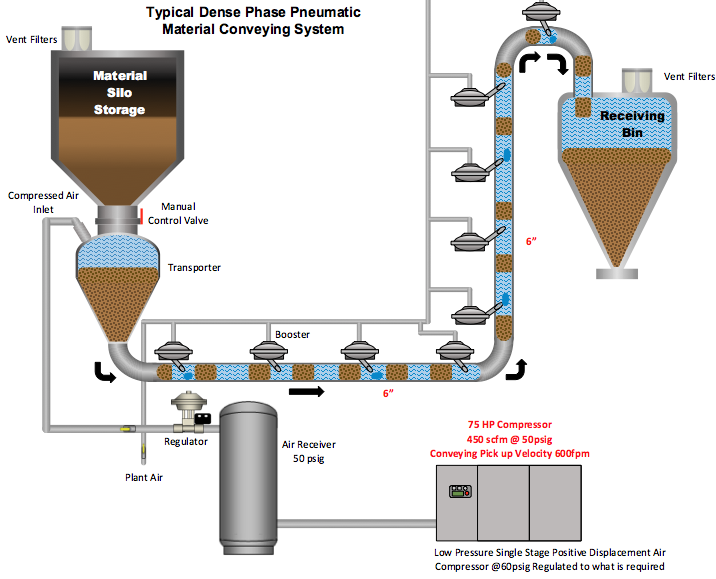

Qs scfm S X conveying rate lbmin Calculate the required operating pressure P psig. Calculation methods to size a dense phase bulk solids pneumatic transport line. The research work carried out on the.

From David Mills Pneumatic conveying system design guide the solid loading ratio ɸ is 05. Vacuum conveying is also used for conveying toxic materials such as lead oxide. LVM series vacuum conveying systems with cone mills design is widely used in the solid dosage production procedure for transferring and discharging materials consequently it is operated with corollary equipment such as FBG Fluid Bed Granulator or FBD Fluid Bed Dryer for mill and homogenization of granules and evenly qualified granules through sieving agglomerates from granulator according to.

In these topic different parameters like air velocity pressure particle size and shape distance to be conveyed which govern the design of the system are described. Typical conveying velocities are generally in excess of 4000 feet per minute 20 msec and vacuum conveying pressures of up to 15 inches 381 mm of mercury hg.

Q A x V ie.

The material is fed into the conveying line on a continuous basis by vacuum which is supplied by a low pressure positive displacement blower. X 25 d 0076 m 76mm 3 Pipe Diameter System Pressure Loss considering 1 PSI100 ft 791 PSI 8 PSI Roots Blower required 4116 m3hr 791 PSI Select Model Expo 1 From Everest Blowers Standard Product Catalogue Q FAD At Inlet Of Blower 4116 m3hr 242158 CFM P Differential Pressure across the blower 791 PSI N Blower Operating Speed 3420 rpm BHP Power Consumption 1243 BHP Recommended Motor 15 HP2 Pole Calculations. The material is transferred in a network of tubing from the pick up point or source to the customers process. Q A x V ie. The material is fed into the conveying line on a continuous basis by vacuum which is supplied by a low pressure positive displacement blower. Depending on the conveyed material most pressure and vacuum dilute phase systems have an air velocity between 3500 and 9000 fpm and most pressure and vacuum dense-phase systems have a 3000-fpm or lower air velocity. The bulk density of a material is one of the first indicators of design in terms of sizing various system components such as vacuum receivers and air sources. The calculations for the design of a dilute phase conveying sys-tem are based on determining the pressure drop that is gener-ated in the system due to the flow of gas and solids. Air conveyor design.

Calculate the volume of free air Qs required. The calculation result should be the capacity at a certain pressure drop. P HPS X PF. Determine the Saturation S hpton HP pipe velocity v and Pressure Factor PF values for the conveyed product from the published saturation table. This lecture series is presented by Laboratory for Particulate and Bulk Solids Technology Thapar Institute of Engineering and Technology PatialaThis video. I would be very appreciate if someone can give me some instruction on that issue. In a dilute phase system.

Post a Comment for "Vacuum Conveying System Design Calculation"